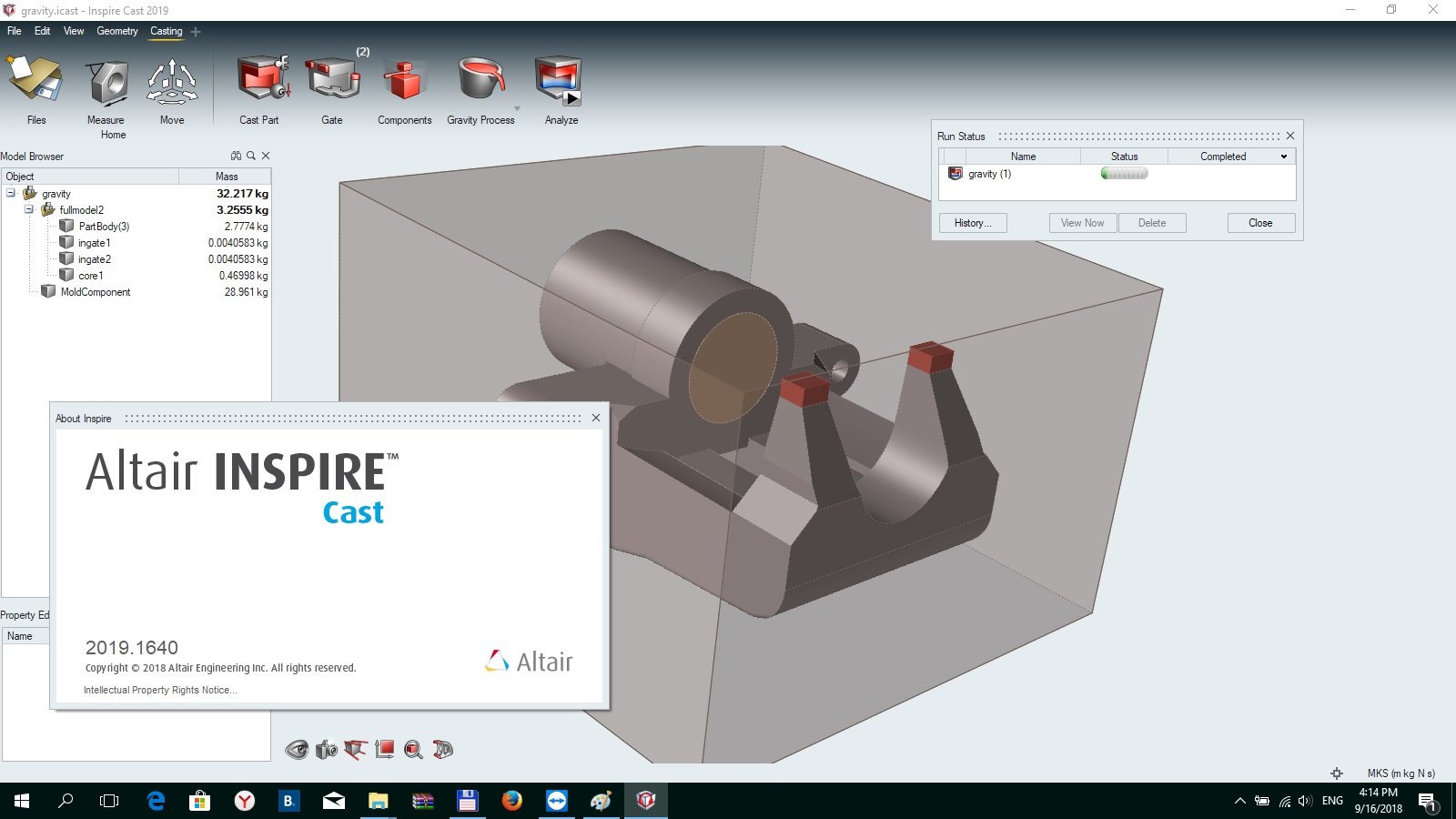

Inspire Cast uses the finite element method. Inspire Cast allows the user to review the entire casting design including the mold cavity, cooling system, channel, exhaust system, and air con, while assisting with mold design and inspection, casting parts. Inspire Cast allows for quick and simple injection port simulation - just choose the size and position and then Inspire Cast will automatically generate the injection port. Optimization of spray port design and location

Inspire Cast is not only easy to use, but its accuracy is also very high. Casting simulation becomes much easier using the 'molding engineer language' in the software. Altair Inspire Cast is a software that helps assess product's casting feasibility and simulates in-depth metal casting.

0 kommentar(er)

0 kommentar(er)